TAICHUNG, Taiwan (BRAIN) — As the industry gathered here last week for Taichung Bike Week, a low-key but important OE event, companies are struggling with pockets of high inventory, pervasive fear of discounting, wars that are disrupting supply chains and markets, historically high U.S. tariffs, and high fuel costs in Europe, among other disruptions.

While some suppliers are more optimistic than others, the global bike industry remains in a state of disquiet for the next season, at least.

“We are entering a danger zone,” said Salvatore Truglio, brand manager for the Prologo saddle brand, referring to multiple factors that could disrupt the market in the coming months. Prologo, based in Italy, does all its saddle manufacturing with Velo in Taiwan.

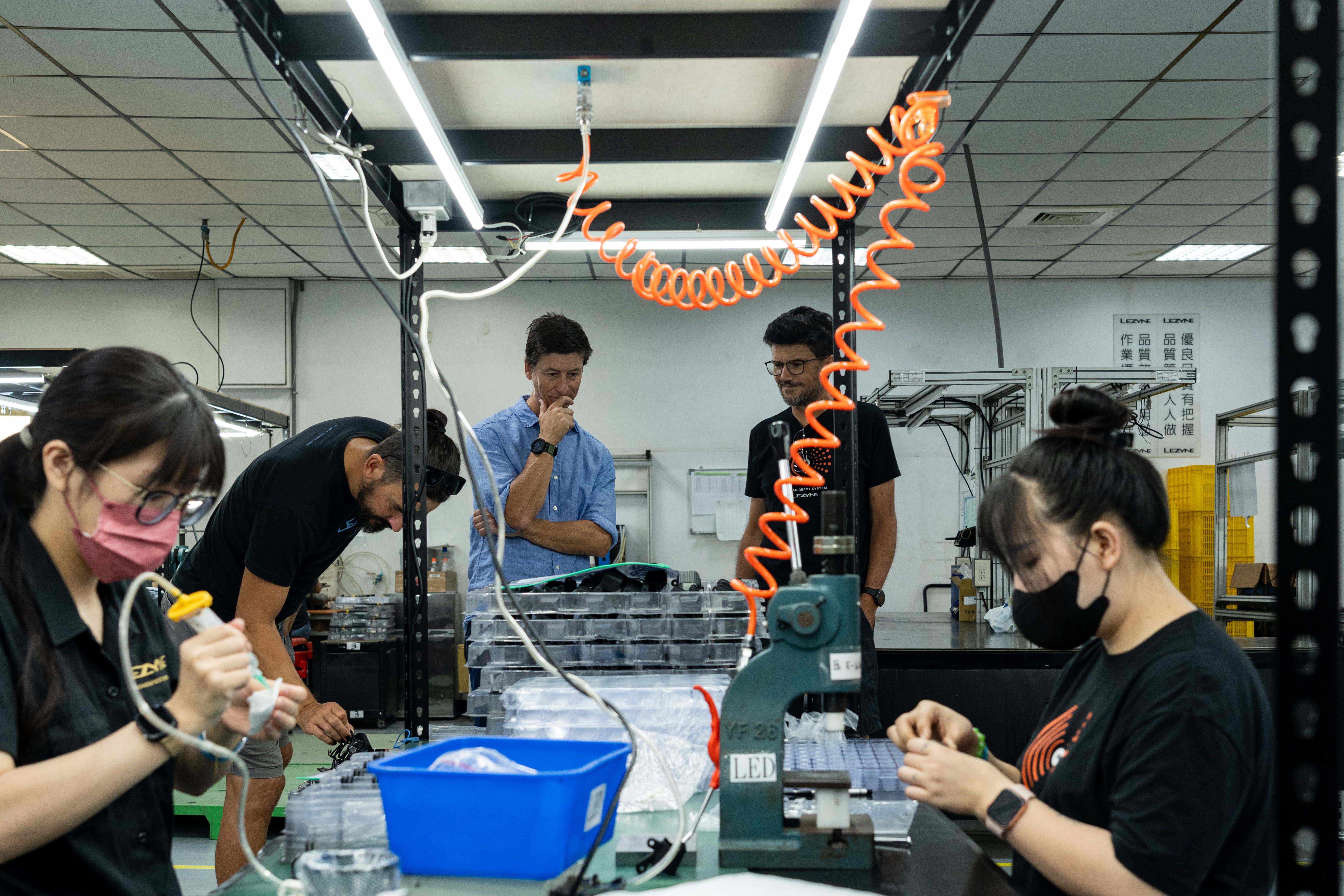

Over the five somewhat sweltering days BRAIN spent in Taichung we enjoyed long discussions with industry representatives from the U.S., Europe and Asia about the state of the global market, re-shoring, tariffs, and expectations for the coming years. We also visited Giant Group's headquarters and cycling museum, ACT Labs' Taiwan facility, Lezyne's CNC and assembly factory, and Tektro's brake factory and headquarters, which are each short Uber trips from the TBW hotels.

Some suppliers to bike brands said they are seeing new signs of life after a long period when brands delayed the launch or development of new platforms and models for fear of competing with old inventory in the channel.

Johannes Huseby, WTB’s director of global OEM sales and product vision, said tire, saddle and wheel orders from bike brands are up this year over last. “Companies are coming out with new models, new platforms, again. It’s good to see,” Huseby said.

Huseby said interest in 32-inch wheels is growing, driven in part by brands hoping to bring out models that are differentiated from old inventory. “They’d like to have something they can sell at full price,” he said.

Huseby said interest in 32-inch wheels is growing, driven in part by brands hoping to bring out models that are differentiated from old inventory. “They’d like to have something they can sell at full price,” he said.

The new wheel size is a promising niche (probably limited to hardtail or short-travel XC bikes in the first year) but in the bulk of the market, discounting remains a major concern, discouraging the development and release of new products. The managing director of one manufacturer noted, for example, that DJI’s new e-bike motors are enticing to many bike brand product managers. But investing in a new e-bike motor platform is risky in a market still rife with discounting.

“DJI is probably going to be on 10 new models next year, and I had one product manager say to me that four of those will probably be discounted by spring, and then his company would have to discount. It would be fiscally irresponsible to invest in that,” they said. (At TBW, DJI said at least 16 brands will use its motors next year).

Many brands have stalled major platform changes since 2020. One product manager in the BMX market said several years ago his company had its factory strip and repaint finished frames to update bikes for a new season without making any major changes.

Still, as Huseby and others noted, there are signs of life as brands plan new platforms for the 2027 season and beyond.

“Customers are placing orders, it’s getting back to normal,” Tektro CEO Leo Chen told BRAIN during a tour of Tektro’s factory last week. “Another indicator is new platforms on the customer side. We are seeing new platforms, new bikes, in development,” Chen said. He said the developments are for 2027 model-year bikes that will be on the market next summer. “We’re expecting a better recovery in the third quarter next year and into 2027,” he said.

As for this year, Chen said Tektro sales were good in the first half as U.S. brands and distributors, in particular, sought to import products before new tariffs took effect. “In the second half, it’s been a pause; there’s not much ongoing right now,” he said.

US market concerns

TBW attracted Europe-based OE brands like Selle Italia, Prologo, Campagnolo, Schwalbe, Ergon, Deda, DT Swiss, Michelin, Continental, Pirelli, Mavic, SKS, and others, who displayed their wares alongside a much larger number of Asian-based suppliers, large and small. U.S. brands exhibiting included WTB, Stan's NoTubes, Hayes Performance, and Carbon, a 3D-printer company.

Some exhibitors noted a lack of U.S. product managers at the event this year. Several major U.S. bike brands were represented by their Asian staff, with fewer than usual American product managers making the trip.

Because of new tariffs, some European brands have little hope for sales growth in the U.S. in the coming year. Some have reduced their exposure by downsizing their U.S. facilities and staffs.

Because of new tariffs, some European brands have little hope for sales growth in the U.S. in the coming year. Some have reduced their exposure by downsizing their U.S. facilities and staffs.

“The U.S. is less than 10% of our business,” one European brand's global sales manager told BRAIN. “It’s an important market for us, but it’s not critical.”

Vietnam is the new favorite

As the industry exits China, Cambodia is being used by many brands for bike and e-bike assembly. But a true industry cluster is developing more rapidly in Vietnam, many said. Major bike manufacturers like Giant and Astro Tech have factories there, as do OE suppliers including Velo, Schwalbe and others. Tektro is building a Vietnam factory that will open in 2027.

The Vietnam cluster is not fully built out yet, however, so many bikes, as well as parts & accessories including helmets, are being partially made in Vietnam with some manufacturing and assembly steps completed in China or Taiwan before shipment to the U.S., Europe or elsewhere.

For example, Troxus recently asked U.S. Customs and Border Protection for a ruling on the country of origin (CoI) for e-bikes whose frame tubes are made in China and Vietnam, then welded and painted in Vietnam. The frames are shipped to China for bike assembly. CBR ruled the e-bikes are Vietnam-made for tariff purposes, because the frame determines the origin of bikes for U.S. imports.

In another example, China has dominated helmet making for years, and helmet industry members tell BRAIN that China remains the source for most helmet straps and other helmet components, as well as helmet-manufacturing tooling. But some brands are making helmet liners in Vietnam, and assembling helmets there using Chinese and Taiwanese components. CBP has ruled that those helmets are Vietnam-made. Interestingly, many brands still rely on U.S.-made polystyrene pellets, which are shipped to Asia to be expanded into EPS liners for helmets that are then shipped back to the U.S. and other markets.

TBW attendance — and its future

TBW is a casual affair — visitors don’t need to register; anyone with a deep interest in bike manufacturing could walk in off the street (although they might not get invited into some exhibitors' closed-door meeting rooms on the upper floors of the event's hotels). Since no entry badges are issued, it’s impossible to accurately track visitor attendance.

But most exhibitors and other visitors told BRAIN that buyer traffic was down significantly from recent editions, while the number of exhibitors was roughly the same. The president of a U.S. component brand said his appointment calendar was much lighter than last year — just 40 scheduled meetings during the week instead of over 100 last year. He said walk-by visits to his booth were also down. Several attendees noted lodging vacancies at some of the host hotels, unlike previous years.

Before the event, organizers announced that next year’s show will be Sept. 15-18. Organizers also floated the idea of moving TBW to Taichung’s new convention center, which is opening by the end of this year. While the center is an architectural marvel (see photo to the right), exhibitors and other attendees at TBW universally told BRAIN they opposed the proposed move. They said it would increase costs for everyone and distract from the casual networking vibe of TBW’s historic setting spread across three large hotels in downtown Taichung. At TBW, most exhibitors and their customers sleep, eat and drink in the same hotel as their displays.

Before the event, organizers announced that next year’s show will be Sept. 15-18. Organizers also floated the idea of moving TBW to Taichung’s new convention center, which is opening by the end of this year. While the center is an architectural marvel (see photo to the right), exhibitors and other attendees at TBW universally told BRAIN they opposed the proposed move. They said it would increase costs for everyone and distract from the casual networking vibe of TBW’s historic setting spread across three large hotels in downtown Taichung. At TBW, most exhibitors and their customers sleep, eat and drink in the same hotel as their displays.

"It's all about the conversations you have in the elevator or at breakfast or at the bar. A convention center would end that," said Mark Vandermolen, FSA's managing director.

“We don’t need another Taipei Cycle; moving to the convention center would kill Bike Week,” said Kendall Young, a U.S.-based OE sales rep for several brands. Over the last 15 years or more, Young has seen TBW develop as an alternative to brand events held in Taichung including the former RideOn show.

While Taichung officials would like to host one of the city's key industries at the new convention center, organizers have yet to make an announcement and it appears unlikely TBW will move next year. TBW founder Steve Fenton handed over the event and its trademark to the city several years ago.

While Taichung officials would like to host one of the city's key industries at the new convention center, organizers have yet to make an announcement and it appears unlikely TBW will move next year. TBW founder Steve Fenton handed over the event and its trademark to the city several years ago.

TBW has shifted from December to October and now mid-September in the last 15 years. Many said the current timing could be better for the OE sale cycle. Model years have become more fluid since COVID, but by mid-September most brands have already made orders for next year’s bike models (model year 2027 in this case), most said.

However, moving TBW earlier in the calendar runs up against Taiwanese national holidays in early September, Europe’s August vacation period, and Eurobike in June. That has made April’s Sea Otter Classic in California (following March's Tapei Cycle) an important OE event, many said, with some OE brands hosting global product managers in dedicated OE sales tents or rooms at the Sea Otter, or in the Monterey area. Product managers from Europe and Asia now regularly come to Monterey.

Some brands also noted the increased importance of Sea Otter Europe, held in Girona, Spain, the weekend after TBW closed. Several brands planned product launches around that event this year, and some potential European industry visitors opted for Girona instead of Taichung, while a few tried to attend both events.