RED WING, Minn. (BRAIN) — Industry companies in the Upper Midwest are lending their support to a local community college's new engineering program focused on the design and fabrication of bicycles and their components.

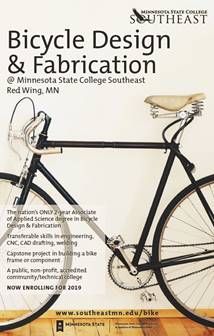

Next fall, Minnesota State College Southeast's campus in Red Wing, located 60 miles southeast of the Twin Cities, will introduce Bicycle Design & Fabrication, a two-year associate of applied science degree program. In addition to preparing students to enter the bike industry, the coursework was designed to equip them with the engineering skills to work in the region's high-tech manufacturing economy.

"Where we live in the Upper Mississippi (River) area is the most engineering- and manufacturing-dense area of the country. It's unbelievable how much high-tech employment there is here," said Travis Thul, MSC Southeast's dean of trade and technology. "And you combine that with a very, very low unemployment rate, and it becomes very difficult to try to reach out to young people and inspire them to get into this unbelievably critical career field, which includes welding, machining, fabrication — the core, core technical programs that are critical to our long-term viability."

Major manufacturers in the college's area include Red Wing Shoes, Valley Craft Metal Fabrication, Gemini Manufacturing and 3D printing company Protolabs.

The bicycle program was inspired in part by the college's highly popular Guitar Repair & Building curriculum track, which teaches skills translatable to woodworking and other crafts. But the guitar program does not support the region's economic base in advanced manufacturing, Thul noted.

"When I was charged with reaching out to the next generation of technical students and training them on these mission-critical components, I asked myself, 'What application has emotional appeal, like the guitar does, while still being able to translate these very important technical and employable skills?' " he said. "I'm an engineer, and I've got friends that are engineers who have spent more money on bicycles than probably on their home or their car. It became clear there's an emotional attachment to the bicycle among a very large swath of our population. But if you look at the bicycle, it's also the perfect example of fine engineering skills."

In addition to welding and machining, those skills include metallurgy, working with composites, mechanical design, CAD drafting, rapid prototyping and thermodynamics.

"The bicycle is the culmination of every applied engineering skill set into one application," Thul said.

While the program doesn't launch until next fall, students can begin work on their general education requirements for the two-year degree this spring.

The curriculum is being designed in collaboration with an advisory committee composed of representatives from such local industry companies as Trek, QBP, Park Tool and Hed Cycling. Trek and retail chain Erik's Bike Shop have also helped recruit faculty for the program through their social media, Thul noted.

"The industry has committed to participating in whatever way they can. For example, the engineer we're working with at Trek is an alumnus of one of our sister campuses. The hope is that we'll be able to leverage their expertise on a regular basis," he said.

Luke Strauss, QBP's engineering manager, said that having a degree in this area would be a benefit to potential employees at his company or in the bike industry generally. "As we continue to build and grow our design and prototyping capabilities, it will be great to have a growing pool of students to hire from for internships and careers," he said.

Industry companies interested in participating in the Bicycle Design & Fabrication program can contact Thul at tthul@southeastmn.edu or 507-453-1422.

For more information about the program and to apply, go to southeastmn.edu/bike.