FRIEDRICHSHAFEN, Germany (BRAIN) — Before the Eurobike show floor opened, journalists gathered around the coffee bar in BMC's sleek and modern booth for a critical cup to fuel the day ahead. Besides proving they can pull a good shot of espresso, the Swiss company also showed editors a glimpse into what will be coming down the pipeline from BMC.

BMC product managers introduced its Impec Advanced R&D Lab, located in its factory in Grenchen, Switzerland, which it opened in 2007 to support the production of the BMC Impec woven carbon fiber road bike. Frames are turned out of the fully automated facility, starting with the 128-spindle wheel called the Stargate that braids raw carbon fiber into a tube based on specifications programmed into the computer.

The Impec Lab evolved out of the factory, and focuses largely on innovation as opposed to production, and according to BMC, is a playground for any and all ideas that its team of about 15 employees conceive.

And the result of those ideas is also the star of BMC's Eurobike exhibit: the space-age looking Impec concept bike BMC has kept under wraps until now. Encased in glass in the BMC booth, the one-sided prototype was conceived, engineered, modeled and built at the Impec factory. BMC's head of development, Stefan Christ, told the media that because everything is done in one place, the BMC team can put ideas into action immediately.

"We can come up with an idea and have a prototype very quickly," said Christ. "We have the capacity to do that since we don't have to send drawings to Asia and wait for them to be made." The Impec concept bike took just four months from initial inception to working prototype.

Ignoring UCI standards when designing the future iteration of the Impec also gave BMC engineers the liberty to innovate. "We wanted to create a bike we want to ride," said Christ. "And so we were able to integrate all the features a rider might need into the frame."

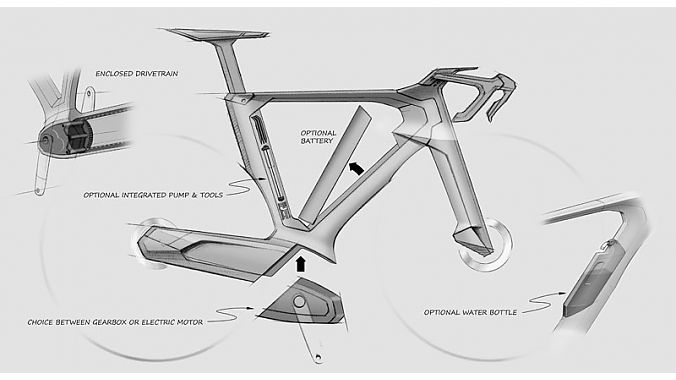

These include an integrated water bottle on the downtube, battery storage capability and pump, tube and tool storage. These features are completely modular so riders can change parts out to suit their needs and preferences.

The Impec prototype also features a number of technologies BMC is working to patent, including a twin stem and seatpost for better aerodynamics and stiffness. Engineers have also conceived a port into the chainstay that will direct airflow to disc brakes to aid in cooling on long descents, and integrated disc brake calipers improve aerodynamics.

BMC also created an integrated gearbox to replace the traditional derailleurs for less drag and maintenance. The frame has space for either the gearbox or an electric motor — something not yet seen on performance road bikes (Editor's note: unless you believe certain skeptics), but that Christ said could appear in the not-so-distant future.

When the Impec Concept bike will go into production is not yet known, but Christ said that the Impec Lab will allow BMC to remain at the leading edge of rider demands and trends because the company can quickly respond with relevant products. "We can test our solutions like no one else, all in one place," he said. "So that allows us to stay ahead of the game."